Product Development of IBM

Development of Plastic components parts or any parts made with thermoplastic starts with the technical discussion with the clients and our expert team. With use of 3D models we are able to visualize the part being created or may have other methods as well to feel the parts finish, texture etc. But sometimes there can be way more things which cannot be known just by touchy feel or just by visualization.

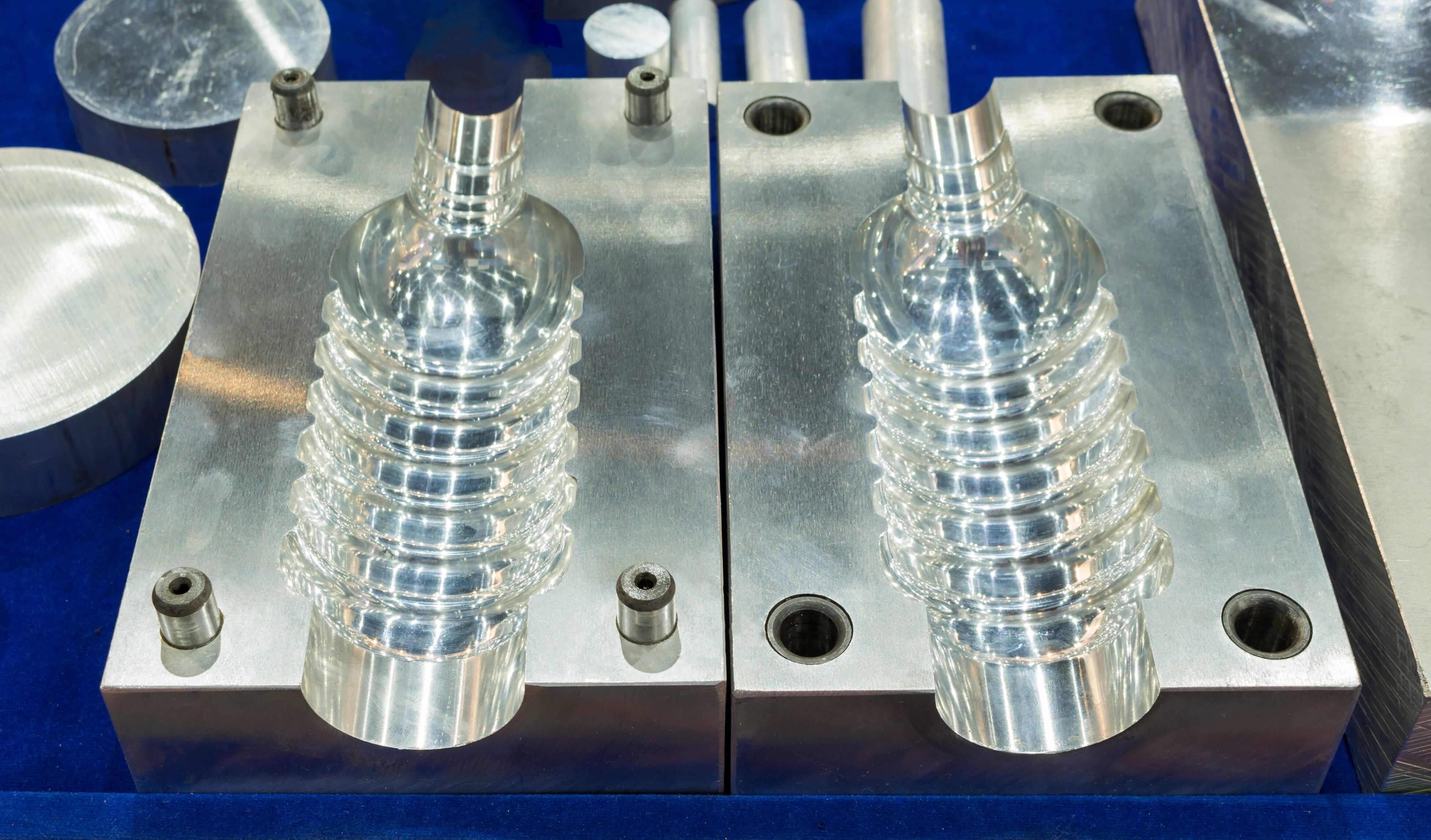

In this regard, MAHADEVI TOOLS may construct smaller cavitation tools, known as pilot moulds, for our customers in the medical device/disposables industry as prototypes for product development. Mahadevi Tools specializes in supplying the medical device market, including disposables and long-term products such as medical diagnostic, treatment, and instrumentation, and can provide insight that can help eliminate some of the hurdles and/or manufacturing challenges that can arise during product development.

We provide a wide range of services, including product development and plastic part design support. This assures that the new-product design engineers' drafted product or components are genuinely designed for "mould-ability" or machinability. For a number of reasons, a part that appears nice on the screen may not be suitable for injection moulding.

In addition, we may give unique and creative input into the design of the product or component, which can result in benefits such as lower cost-to-manufacture by integrating many components into a single component. Instead of two or three separate moulds, the product or its various components can make use of advanced mould technologies like in-mould labeling, in-mould decorating, and in-mould assembly, or new moulding technologies like multi-shot or over-moulding, in which two or three different materials or colors of material can be injected into the same mould to produce a complex part. For ergonomic or aesthetic reasons, a hard thermoplastic substrate can be over moulded with a thermoplastic elastomer (TPE).

Mahadevi tools, with their strong R&D capabilities, may help with product development in a variety of ways. We can provide recommendations that will save money not only in the prototype phase, but also in the production tooling phase – we can do this by using 3D modelling to create extremely valuable conceptual pictures of the component or product.