About Us

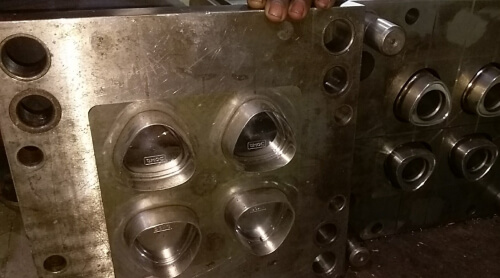

Our mould construction is specialised in the production of high performance Injection moulds, Injection Blow Moulds & Hot runner moulds in the field of Household, Pharmaceutical & Industrial products. These moulds can be delivered in a very short span of time.

The tools used for the production of Beverage & Drinking water caps, CTC caps, Flexible Packaging Spouts & Caps, Closures for Medical and Pharmaceutical Application, Spray Actuators, Flip-tops for Tubes & Bottles, Caps for Cosmetic & Personal Care, Caps for Industrial Packaging, Spoons and forks are manufactured on site by our team.

Range Of Services Includes :

Concepts and Improvements in the field of mould manufacturing, tool design & construction.

R & D towards design of new plastic products, continuous development of existing plastic parts for betterment & modernisation.

Our engineers working in development and concept generation are specialized in realizing the minutest of customer requirements & demands and by working in tandem with the tool makers helps us achieve the highest levels of customer satisfaction and results.

Who We Are :

MAHADEVI TOOLS. Is a growing young company, based in the Industrial zone of THANE.

The Managing Director cum Founder, Mr. NARAYAN.T.SALIAN established the company in the year 2000 in the industrial zone within Mumbai city.

The Ever Growing, Ever Evolving team around Mr.SALIAN is highly educated and extremely experienced, furthermore the team is motivated to accomplish projects that surpass their previously set records and set newer benchmarks for themselves as well as the Indian tooling industry.

Catering to a vast and ever increasing segment of the injection moulding industry, MAHADEVI TOOLS has carved a niche for itself as not just a mould manufacturer, but for providing turn-key solutions to the caps and closure industry, with durable, reliable and fully automatic high speed moulds ready to be interfaced with robots and other post moulding operations. With our presence in the global market, we further aim at increasing our reach and providing end-to-end solutions to the worldwide injection moulding industry. We take up our customer service and tailor-made consulting on the highest priority basis. This is considered to be our leading principle in the company's philosophy. We are able to make all efficient and reliable moulds because of our continuous technological research and all our past experiences.

Before turning on the computer and drawing lines we simply aim at knowing deeply our customer's exigencies, understanding why he wants to carry out new production, checking each aspect, going beyond the mere project to create something unique and absolutely suited the new need.

The difference in our way of working is the same as you get the readymade dress from a shop and the one which you made from a tailor as per your requirement.

For this we follow the step by step procedure.

- First we understand the exact requirement of our customer. For that we take references of their sketches, dummy models etc. We also understand what functionally are the most important points in that product i.e. the shape, the type of hinge, the type of dispensing, the fitment with another matting product etc.

- After this we do the product designing considering all above points and make 2D drawings as well as 3D models.

- While doing the engineering drawings as well as 3D models we also consider in mind that the product should be feasible to make the mould as well as the mould should not be too complicated to function.

Design

MAHADEVI TOOLS Pursue for excellence begins right at the design stage by experienced designers assisted by latest CAD/CAM facilities to meet the requirements of any complex 3D profiles. Our design engineers, well experienced in their profession, are assisted by latest software's like

- Siemens Solid Edge ST8

- Delcam R14

- Autocad 2013

- ZW 3D CAD

- Solid Works 2018

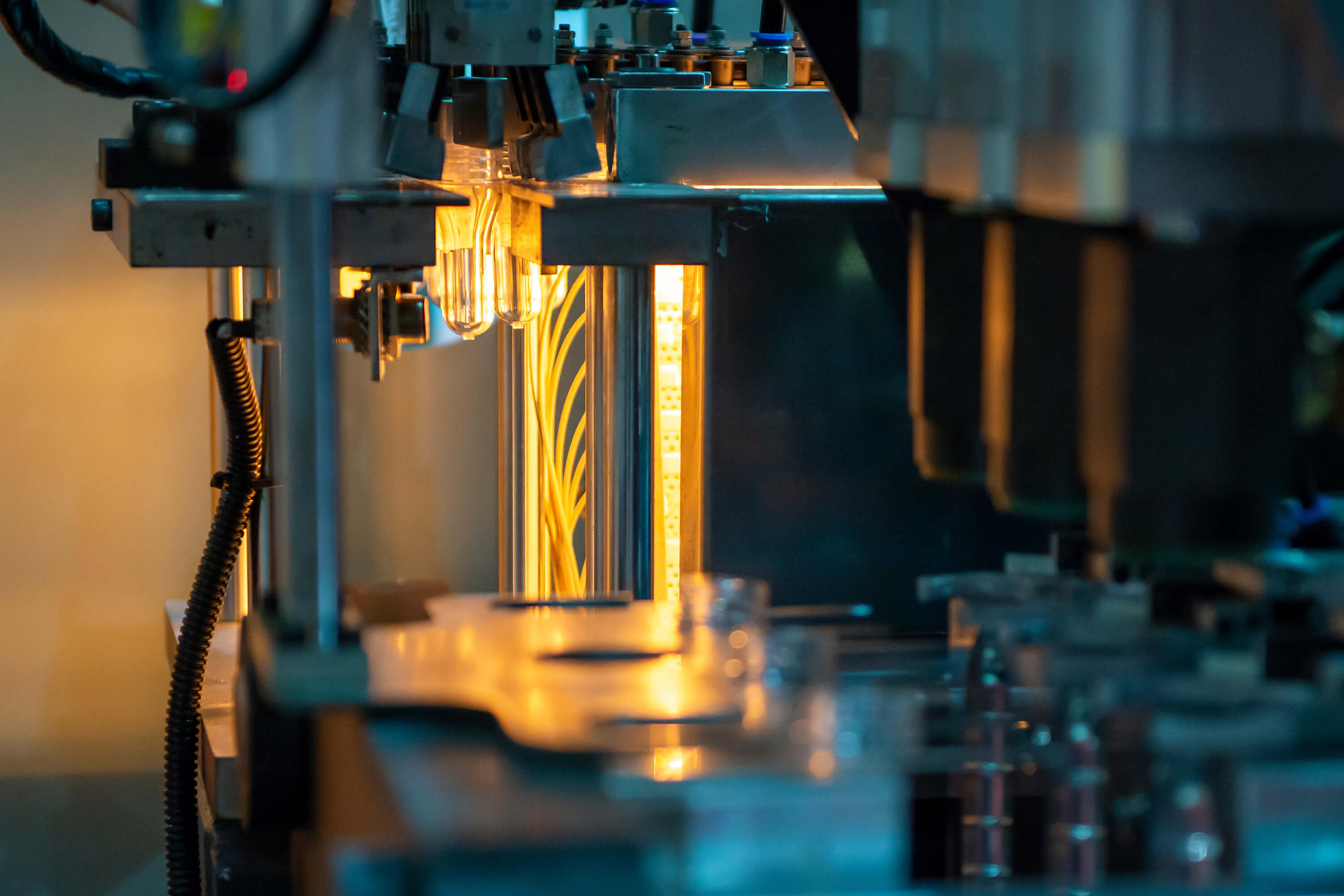

Mould Testing Unit

We get our mould tested with the help of trails on different moulding machines as per the mould size and suitability. This includes temperature of mould, cycle time, pressure and various other factors. Each trial is done under the guidance of our team.