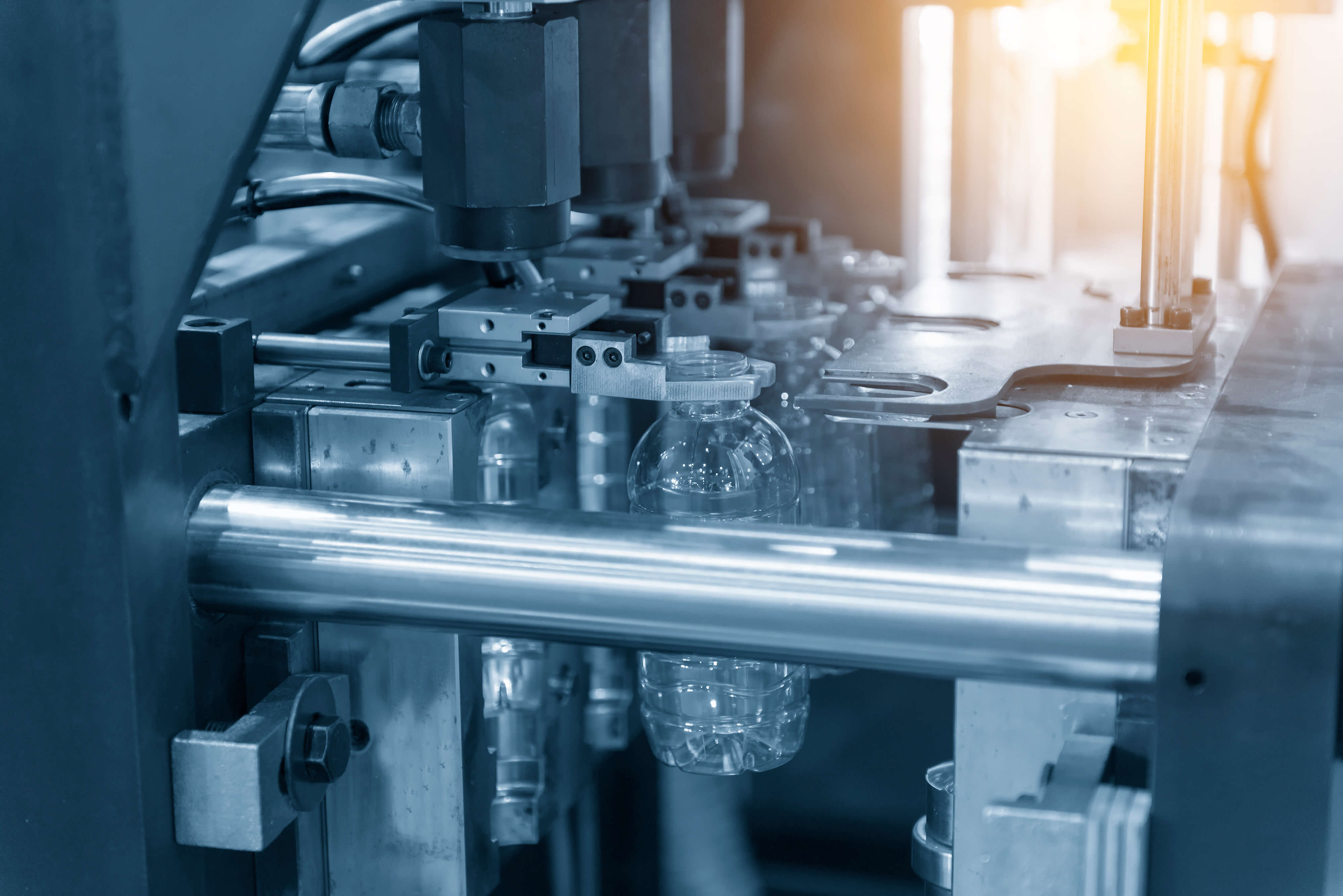

INJECTION BLOW MOULDING

Blow Moulding is the technique of inflating a heated, hollow thermoplastic preform or parison

inside a closed mould to conform to the mould cavity's shape. This procedure may be used to make

a wide range of blow moulded hollow items, including plastic bottles, from a variety of polymers.

Every year, the injection blow mould (IBM) method creates billions of plastic containers. These

containers, which range in size from 1 mL to 2 litres, are used all over the world for a variety

of applications ranging from medicines to cosmetics to automotive

to domestic usage, and they fulfill stringent criteria of uniform weight, volume, and tolerances.

BLOW Mould PLASTICS.

The thermoplastic raw materials used in the blow moulding process are tiny pellets or granules that are first melted and moulded into a hollow tube known as the parison. A broad range of thermoplastic polymers may be used to make blow moulded items, including:

- Low Density Polyethylene (LDPE)

- High Density Polyethylene (HDPE)

- Polyethylene Terephtalate (PET)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

INJECTION BLOW Mould APPLICATIONS

Injection blow moulds may be used to make a wide variety of items. Plastic, hollow, and thin-walled parts are typically made from blow moulds. These sorts of items are often utilised and come in a variety of forms and sizes. The following are examples of blow moulded parts:

- Water & soda bottles

- Shampoo bottles

- Oil jugs

- Milk containers

- Storage tanks

- Plastic drums

- Tubs

- And more

INJECTION BLOW MOULDING PROCESS :

The material is injection moulded during the injection blow moulding process. The heated material is then transferred to the blow moulding station, where it is blown into a bottle and allowed to cool while still on the core pin. The bottle is then indexed and discharged to the next station. Extrusion blow moulding provides for more accurate detail in the neck and finish (threaded) region. Injection blow moulding allows for more precise detail in the neck and finish (threaded) area. Because there is very little direction in the injection blow moulding process, there is limited increase in physical qualities.

PROCESS AT MAHADEVI TOOLS FOR BLOW Mould MAKING :

When a customer offers us a concept for a

new bottle design, we first evaluate it: Is this a design that can be used in the injection blow

or injection stretch blow processes? A meeting is held at the start of every project to confirm

technical aspects and client requirements.

We are dedicated to aiding clients throughout the process until all of their needs have been

addressed. We develop ways to guarantee that our customers are happy using a cost-effective

procedure that does not sacrifice quality. When the production mould is delivered to the

customer, our staff checks that the mould is operating properly and producing bottles that meet

the customer's specifications. Our team's mission is to make it as simple as possible for our

clients to not only get the greatest service, but also to obtain the best price.

OUR EXPERTS FOR BLOW MouldS :

We are blow mould professionals, and as a top-tier manufacturer, we are committed to a large client base that requests containers in a variety of shapes. We are able to retain excellent relationships with our consumers because of our professionalism and superior customer service. We have the ability to handle a variety of applications and levels of complexity, whether it's rapid turnaround for medium and short production runs or blow moulding in various configurations.

Blow Mould Design: Get The Desired Shapes

Whether the project you're working on

requires a unique form, inventive finishing options, or specific features, we'll be there to

help. We are ready to work on cost-effective solutions to fulfil the goals and needs of our

customers. Here's all you need to know.

We have been offering consistent service and high-quality moulds in order to meet your needs.

We have the knowledge to meet your needs, whether it's a one-of-a-kind blow mould design or generating one-of-a-kind injection moulded components.

We encourage customers to peruse our product line in order to discover the best alternative for

their requirements.

Our company's manufacturing line focuses in tracking, providing excellence, and improving output

quality.

Our teams of specialists come from the disciplines of design and engineering, and they would be

delighted to collaborate with customers on blow mould manufacturing.