Product Development -

A Key Asset for Mahadevi tools

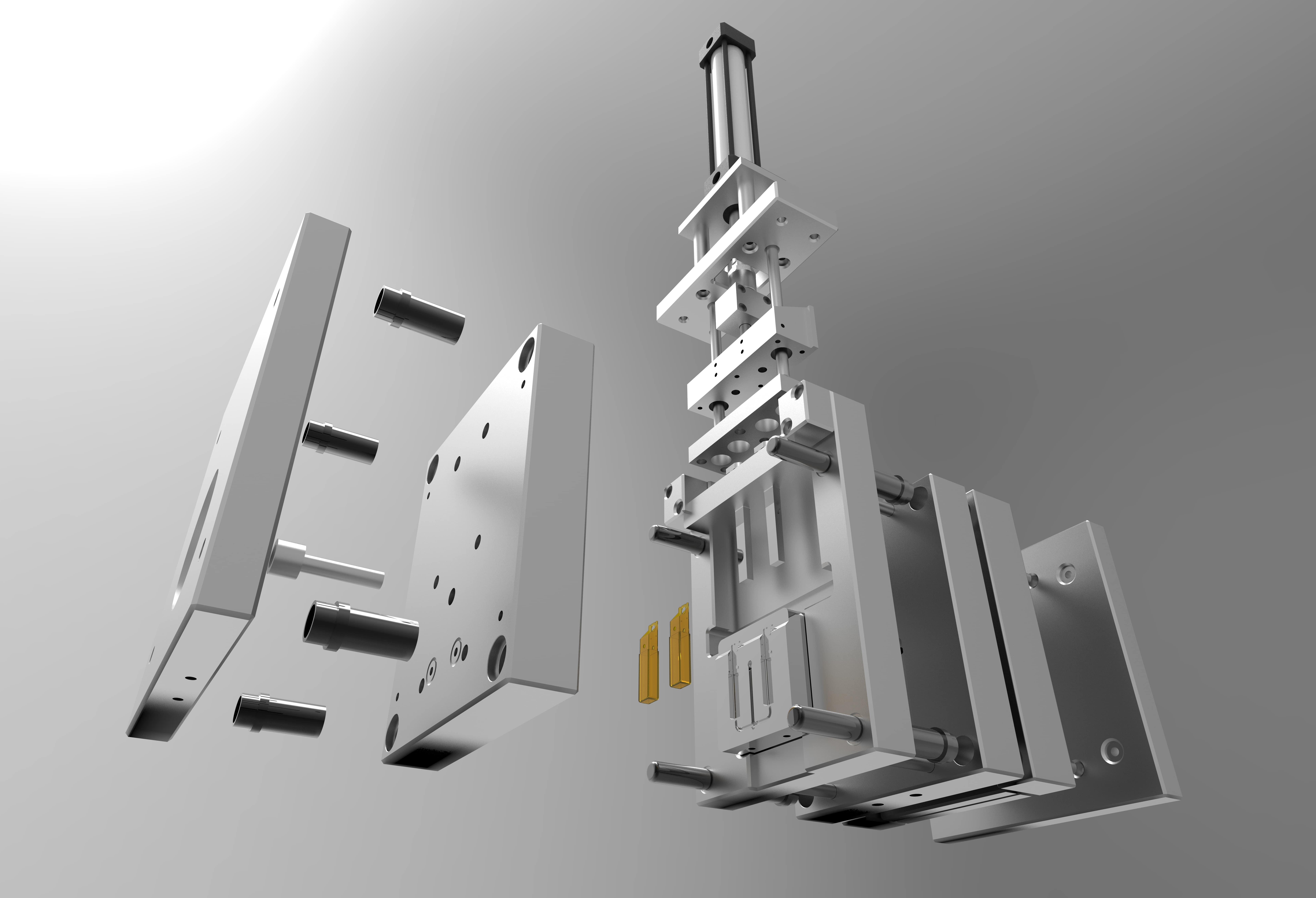

Development of Plastic components parts or any parts made with thermoplastic starts with the technical discussion with the clients and our expert team. With use of 3D models we are able to visualize the part being created or may have other methods as well to feel the parts finish, texture etc. But sometimes there can be way more things which cannot be known just by touchy feel or just by visualization.

In this regard, MAHADEVI TOOLS may construct smaller cavitation tools, known as pilot moulds, for our customers in the medical device/disposables industry as prototypes for product development. Mahadevi Tools specialises in supplying the medical device market, including disposables and long-term products such as medical diagnostic Read More...

Our Services

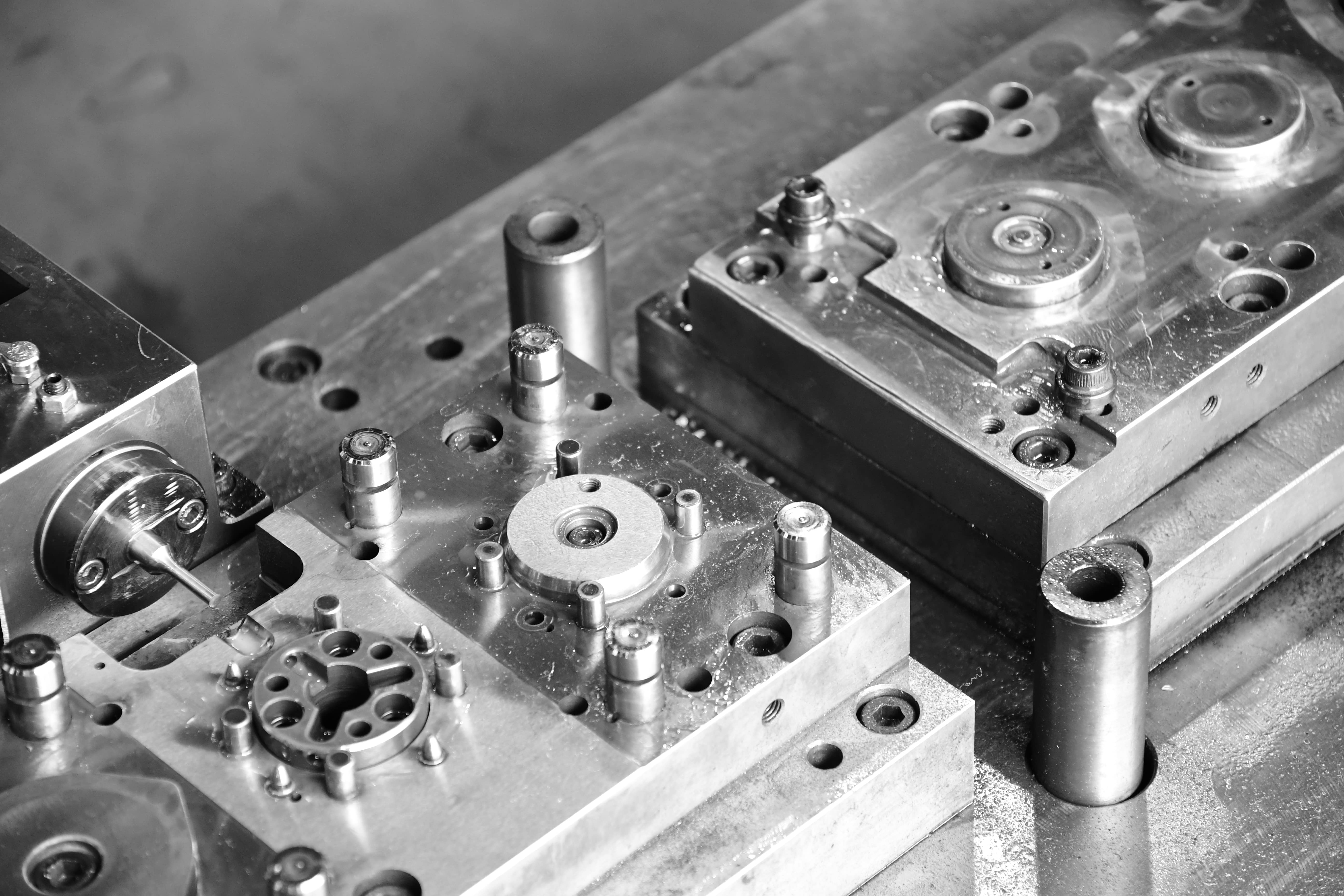

Mould Quality Process

The Mould manufacturing process is a complicated process that includes design, processing, assembly, and debugging procedures before it can be used.

Mould Steel Material

Mould steel is a material that is used to manufacture the moulds. The quality of mould directly impacts the quality of processing technique, precision and output of products and more.

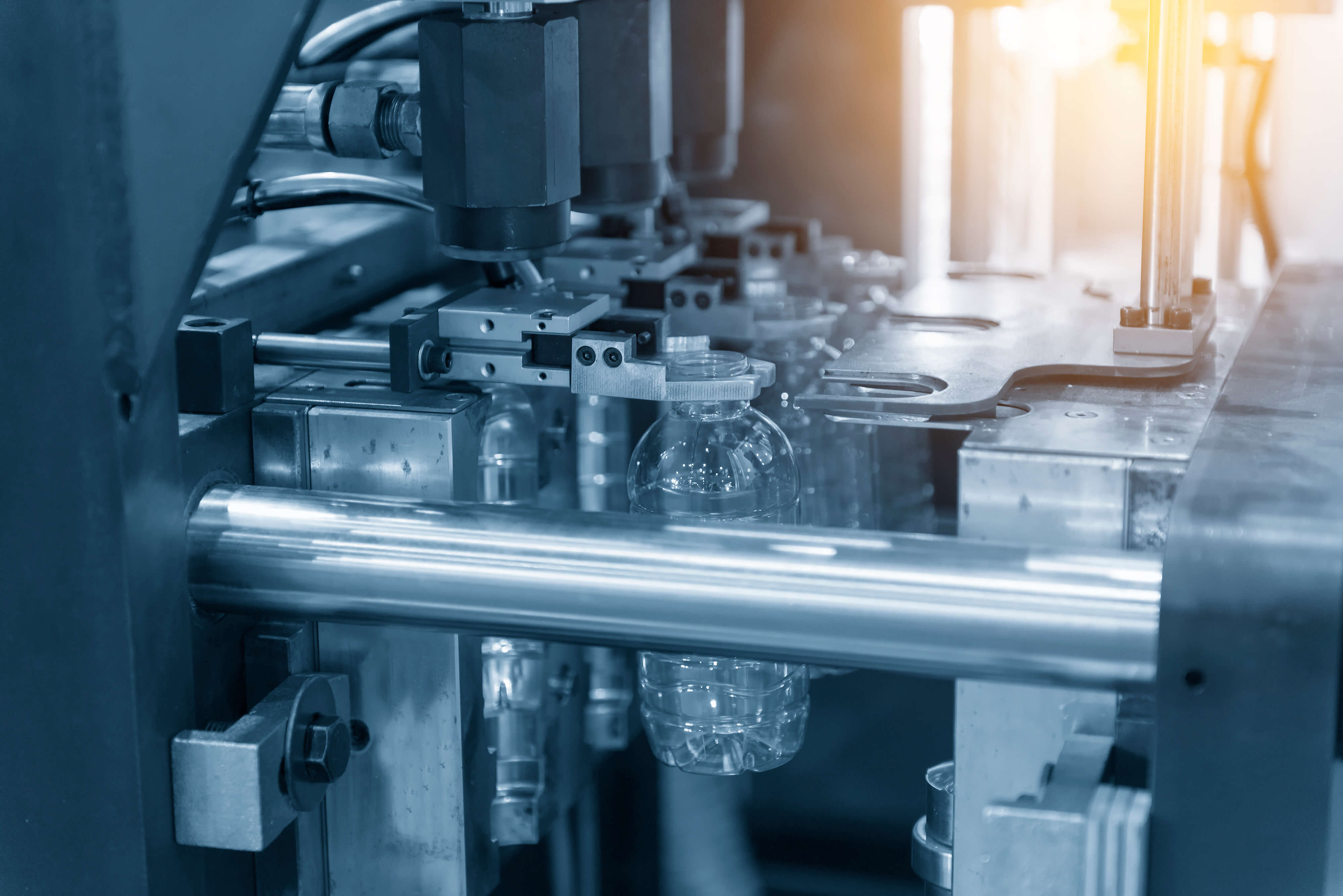

Mould Trial Process

Set the mould to the centre of the prescribed temperature range. We also ensure that the actual mould temperature is correct throughout production.

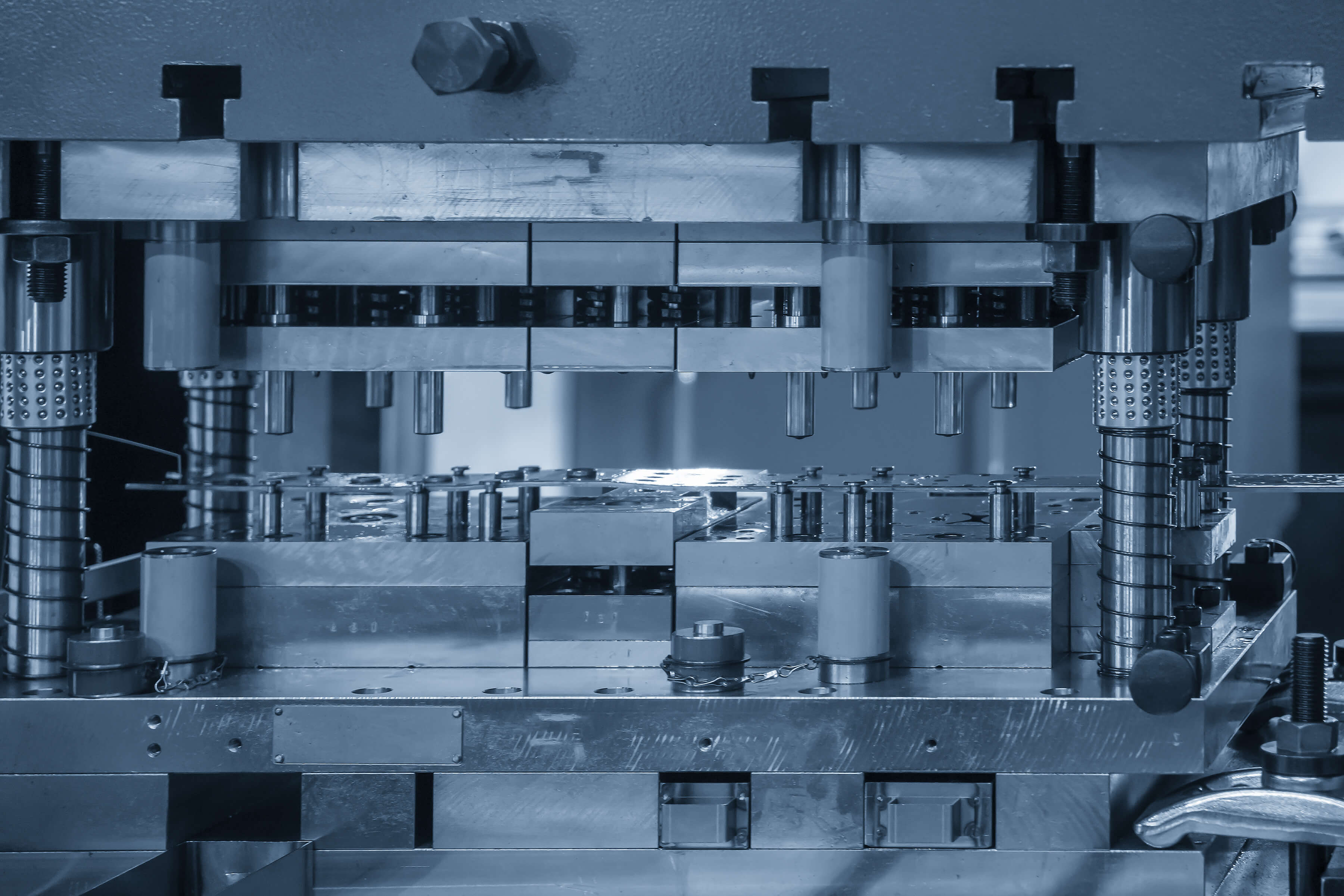

Technical Support

The mould manufacturing process is a complicated process that includes design, processing, assembly, and debugging procedures before it can be used.

3D Printing

3D printing, also known as additive manufacturing, is a technique for layering a three-dimensional item using a computer-generated design.

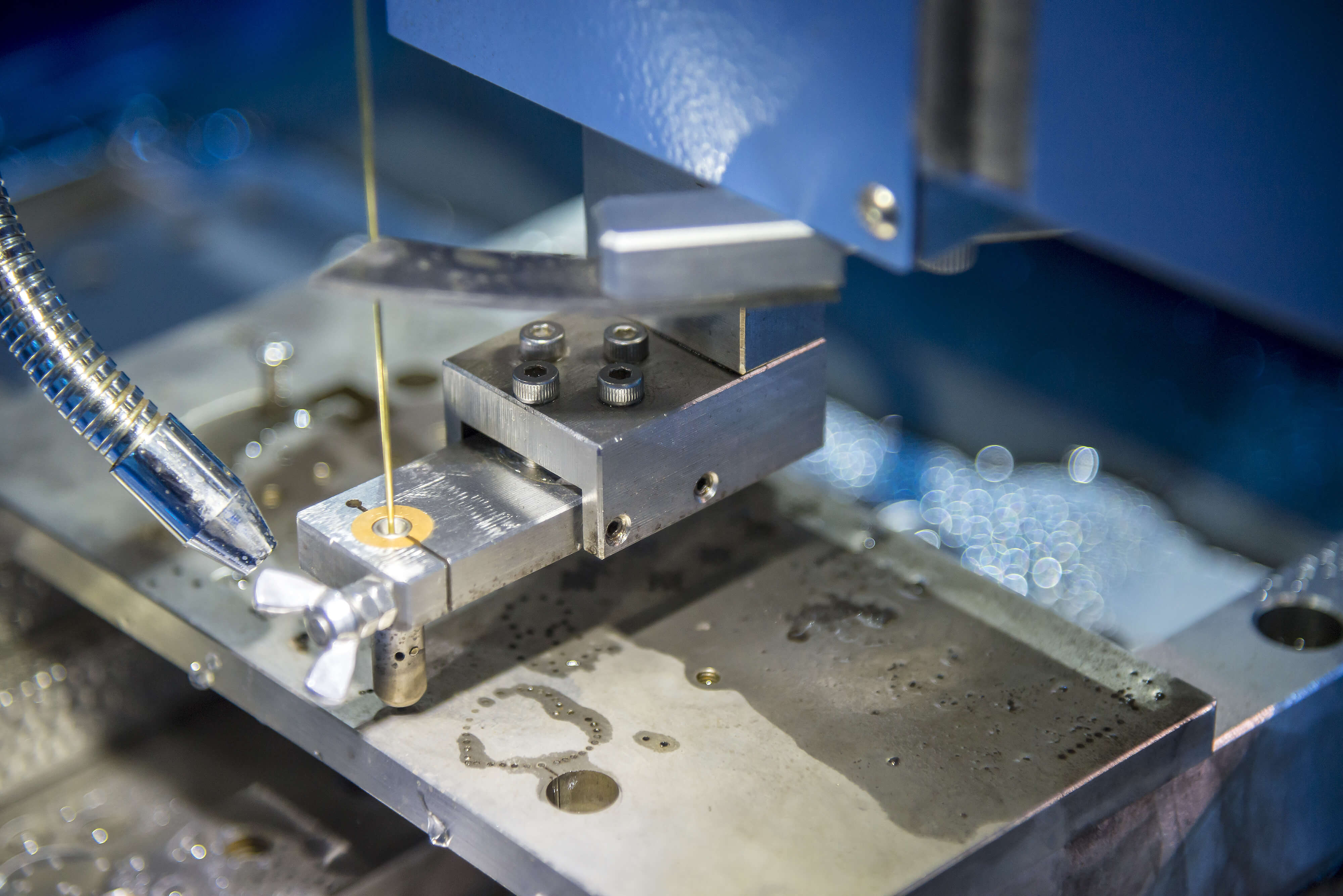

Tooling Cost

One of the most difficult issues we have as mould manufacturers is competing in the worldwide market to create tooling at a low cost while maintaining part quality.